Material:

Outer: irradiation crosslinked modified polyolefin material

Inner layer: hot melt adhesive

(Single-wall type thick-walled tube does not involve the inner layer)

Shrink ratio: 3.5: 1 4: 1

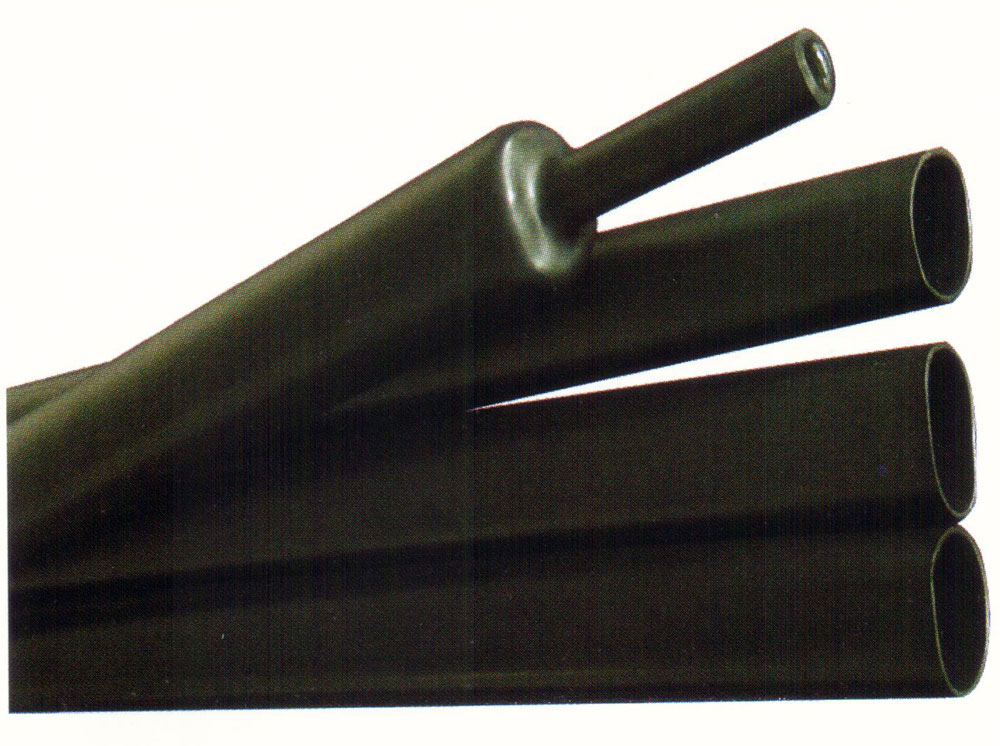

Features:

- High shrink ratio, the greater the diameter of the quilt was coverage;

- Black sleeving, has excellent UV resistance;

- semi-rigid walled polyolefin material has excellent electrical insulation propertiesand mechanical protection properties;

- Minimum fully shrink temperature: 135 ℃.Application: High magnification of the polyolefin heat-shrinkable tubing material with good electrical insulation properties and mechanical protection properties, its high rate shrinkage characteristics, particularly suitable for a wide range of sizes harness connection or component connection, the thicker type of wall thickness characteristics, especially for electrical insulation protection and mechanical protection, inner layer of hot melt adhesive in high-voltage power cable connected to the connecting member can play a waterproof seal.

Introduction

| Item | Test method | Indicator |

| Range of continuous operating temperature | IEC216 | -50℃~110℃ |

| Tensile strength | ASTM D2671 | ≥14MPa |

| Elongation at break | ASTM D2671 | ≥400% |

| Tensile strength after aging | ASTM D2671(150℃,168h) | ≥12MPa |

| Elongation at break after aging | ASTM D2671(150℃,168h) | ≥300% |

| Volume resistivity | IEC93 | ≥1.0×10¹⁴ Ω· cm |

| Breakdown strength | IEC243 | ≥20kV/mm |

| Copper stability | ASTM D2671 | by |

| Axial shrinkage | UL224 | 0~10% |

| Concentricity rate | ASTM D2671 | ≥65% |

| Cracking resistance | ASTM D1693(50℃) | No cracking |

| Water absorption | ISO62(23℃,14day) | ≤0.2% |

| Hot melt adhesive (single-wall type sixfold thick-walled tube does not involve) | ||

| Softening Point | ASTM DE28 | 85℃ |

| Peel strength(PE) | DIN30672 | ≥4N/cm |

| Copper stability | ASTM D2671 | No corrosion |

| Antibacterial | ISO846 | by |

Specification

| Specification | Product inner diameter(mm) | After shrinking the inner diameter(mm) | Wall thickness after shrinking(mm) | Standard length(mm) |

| 9/3 | 9 | 3 | 2.0 | 1220 |

| 13/4 | 13 | 4 | 2.4 | 1220 |

| 22/6 | 22 | 6 | 2.7 | 1220 |

| 33/8 | 33 | 8 | 3.2 | 1220 |

| 40/12 | 40 | 12 | 4.1 | 1220 |

| 55/16 | 55 | 16 | 4.1 | 1220 |

| 65/19 | 65 | 19 | 4.1 | 1220 |

| 75/22 | 75 | 22 | 4.1 | 1220 |

| 85/25 | 85 | 25 | 4.3 | 1220 |

| 95/30 | 95 | 30 | 4.3 | 1220 |

| 105/30 | 105 | 30 | 4.3 | 1220 |

| 115/34 | 115 | 34 | 4.3 | 1220 |

| 130/36 | 130 | 36 | 4.3 | 1220 |

| 160/50 | 160 | 50 | 4.3 | 1220 |

| 180/50 | 180 | 50 | 4.3 | 1220 |

| 200/60 | 200 | 60 | 4.3 | 1220 |