Material: Radiation Cross-linked Polyolefin

Shrink Rate: 2:1 3:1

Use:

CYG-MT (HX) marker sleeves are designed to meet the wire and cable marking needs of manufactures with high performance requirements. Made from durable, flame retardant, radiation cross linked heat-shrinkable polyolefin, CYG-MT (HX) maker sleeves can be used in a wide variety of applications. All CYG-MT (HX) meet the performance requirements of SAE-AMS-DTL-23053/5 class I. The marks are permanent immediately after printing and remain legible even when exposed to abrasion, aggressive clearing solvents, and military fuels and oils. The sleeves meet the mark performance requirements of SAE AS81531 4.6.2 and MIL-STD-202 both before and after shrinking.

Futures and Benefits:

- Permanent identification sleeves

- Computer-printable

- Low smoke and RoSH criterion

- Lightweight for aerospace application

- Military specification material and print performance

- 2:1 and 3:1 shrink ratio

- UL Recognized VW-1 all flame tubing test rated

- Quick recovery for heat sensitive areas

- 23053/5

Introduction

| Item | Test method | Indicator |

| Tensile strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

| Elongation at break | SAE-AMS-DTL-23053 | ≥200% |

| Low temperature flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃,4h,No cracks |

| Hot Shock | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃,4h,No cracks, No dripping, No flow |

| Aging properties | SAE-AMS-DTL-23053.4.6.9 | 175℃±2℃,168h No damage (visually intuitive damage) |

| Tensile strength after aging | SAE-AMS-DTL-23053.4.6.13And ASTM D638 | ≥6.9MPa,23℃±2℃ |

| Elongation at break after aging | SAE-AMS-DTL-23053.4.6.13 ASTM D638 | ≥100%,23℃±2℃ |

| Color stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃,24h,by |

| Dielectric strength | SAE-AMS-DTL-23053.4.6.13And ASTM D2671 | ≥19.7kV/mm,23℃±2℃ |

| Volume resistivity | SAE-AMS-DTL-23053.4.6.13And ASTM D876 | ≥1.0×1014Ω· cm,500V(DC),60s |

| Flame retardant | SAE-AMS-DTL-23053.4.6.14 ASTM D2671 UL224 | Self-extinguishing within 60s, more than 25% of the iconic flag is damaged or burned, no dripping and a large area falling |

| Antibody solution performance | AE-AMS-DTL-23053.4.6.11 | No damage (visually intuitive damage) |

| Printing durability | SAE-AS-81531.4.6.2 | Eraser 50 times, the writing is clearly visible |

| Printing solvent resistance | MIL-STD-202G Method 215K | Eraser 10 times, the writing is clearly visible |

Specification

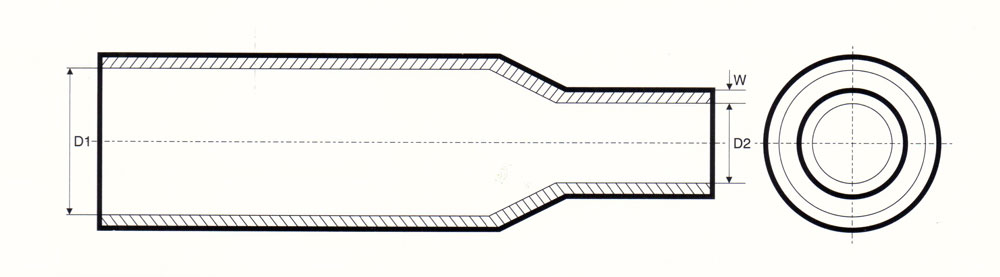

CYG-MT(2:1)

| Specification | Dimension before shrinkage(mm) | Dimension before shrinkage(mm) | Continuous packing (m/plate) | Quantity per reel cassette packaging | ||

|---|---|---|---|---|---|---|

| Diameter(D) | Thickness(T) | Diameter(d) | Thickness(t) | |||

| Ф2.4 |

≥2.4

|

0.27±0.05

|

≤1.2

|

0.51±0.08

|

30

|

2000

|

| Ф3.2 |

≥3.2

|

0.27±0.05

|

≤1.6

|

0.51±0.08

|

30

|

2000

|

| Ф4.8 |

≥4.8

|

0.27±0.05

|

≤2.4

|

0.51±0.08

|

30

|

2000

|

| Ф6.4 |

≥6.4

|

0.32±0.06

|

≤3.2

|

0.64±0.08

|

30

|

1500

|

| Ф9.5 |

≥9.5

|

0.32±0.06

|

≤4.8

|

0.64±0.08

|

30

|

1500

|

| Ф12.7 |

≥12.7

|

0.32±0.06

|

≤6.4

|

0.64±0.08

|

30

|

500

|

| Ф19.1 |

≥19.1

|

0.36±0.06

|

≤9.5

|

0.76±0.08

|

30

|

500

|

| Ф25.4 |

≥25.4

|

0.45±0.08

|

≤12.7

|

0.89±0.08

|

30

|

250

|

| Ф38.1 |

≥38.1

|

0.50±0.08

|

≤19.1

|

1.02±0.15

|

30

|

250

|

| Ф50.8 |

≥50.8

|

0.58±0.08

|

≤25.4

|

1.14±0.18

|

30

|

250

|

| Contraction ratio | Dimension before shrinkage(mm) | Dimension after full contraction(mm) | Continuous packing (m/plate) | Quantity per reel cassette packaging | ||

|---|---|---|---|---|---|---|

| Diameter(D) | Thickness(T) | Diameter(d) | Thickness(t) | |||

| Ф2.4 |

≥2.4

|

0.22±0.05

|

≤0.8

|

0.53±0.08

|

30

|

2000

|

| Ф3.2 |

≥3.2

|

0.22±0.05

|

≤1.1

|

0.58±0.08

|

30

|

2000

|

| Ф4.8 |

≥4.8

|

0.22±0.05

|

≤1.6

|

0.58±0.08

|

30

|

2000

|

| Ф6.4 |

≥6.4

|

0.22±0.05

|

≤2.1

|

0.58±0.08

|

30

|

1500

|

| Ф9.5 |

≥9.5

|

0.20±0.05

|

≤3.2

|

0.61±0.08

|

30

|

1500

|

| Ф12.7 |

≥12.7

|

0.20±0.05

|

≤4.2

|

0.61±0.08

|

30

|

500

|

| Ф19.1 |

≥19.1

|

0.20±0.05

|

≤6.4

|

0.61±0.08

|

30

|

500

|

| Ф25.4 |

≥25.4

|

0.20±0.05

|

≤8.5

|

0.64±0.08

|

30

|

250

|

| Ф38.1 |

≥38.1

|

0.30±0.06

|

≤12.7

|

1.00±0.15

|

30

|

250

|

| Ф50.8 |

≥50.8

|

0.30±0.06

|

≤17.0

|

1.00±0.18

|

30

|

250

|

Note: Other sizes and colors can be special order