Material: radiation cross-linked modified polyolefin material

Shrink ratio: 2: 1 3: 1

Features:

- UL224 and halogen-free products meet environmental standards;

- Label performance to meet SAE-AMS-DTL-23053/5 requirements;

- Packaging diversity, to meet different customer requirements;

- sleeve may be provided directly to standard dot matrix printers and thermal transfer printers;

- sleeve may sided printing, readability;

- Standard color is white and yellow, other colors can be customized;

- have some dirt capacity, identify lasting.

Application:

CYG-MT shrinkable marker sleeves in order to meet the cable manufacturer, fixtures and equipment to identify the requirements of high performance and design. Ingredients sleeve is radiation cross-linked polyolefin, with good abrasion resistance and flame retardant properties. It can be used within an ambient temperature range of -55 ℃ to 125 ℃, widely used in electrical equipment line identification.

Superior performance CYG-MT shrinkable label identifies the casing through the printer to print, even when friction, exposure to extreme oil solvent and military environment can still maintain good identification effect, label material identification performance meets the SAE-AS-81531.4.6.2 and MIL-STD-202F standard. The sleeve has a good fire-retardant properties and insulation, widely used in commercial, industrial, military, automotive and aerospace.

Introduction

| Item | Test method | Indicator |

| Tensile strength | SAE-AMS-DTL-23053 | ≥10.3MPa |

| Elongation at break | SAE-AMS-DTL-23053 | ≥200% |

| Low temperature flexibility | SAE-AMS-DTL-23053.4.6.7 | -55℃±1℃,4h,No cracks |

| Hot Shock | SAE-AMS-DTL-23053.4.6.8 | 250℃±3℃,4h,No cracks, No dripping, No flow |

| Aging properties | SAE-AMS-DTL-23053.4.6.9 | 175℃±2℃,168h No damage (visually intuitive damage) |

| Tensile strength after aging | SAE-AMS-DTL-23053.4.6.13And ASTM D638 | ≥6.9MPa,23℃±2℃ |

| Elongation at break after aging | SAE-AMS-DTL-23053.4.6.13 ASTM D638 | ≥100%,23℃±2℃ |

| Color stability | SAE-AMS-DTL-23053.4.6.15 | 175℃±2℃,24h,by |

| Dielectric strength | SAE-AMS-DTL-23053.4.6.13And ASTM D2671 | ≥19.7kV/mm,23℃±2℃ |

| Volume resistivity | SAE-AMS-DTL-23053.4.6.13And ASTM D876 | ≥1.0×1014Ω· cm,500V(DC),60s |

| Flame retardant | SAE-AMS-DTL-23053.4.6.14 ASTM D2671 UL224 | Self-extinguishing within 60s, more than 25% of the iconic flag is damaged or burned, no dripping and a large area falling |

| Antibody solution performance | AE-AMS-DTL-23053.4.6.11 | No damage (visually intuitive damage) |

| Printing durability | SAE-AS-81531.4.6.2 | Eraser 50 times, the writing is clearly visible |

| Printing solvent resistance | MIL-STD-202G Method 215K | Eraser 10 times, the writing is clearly visible |

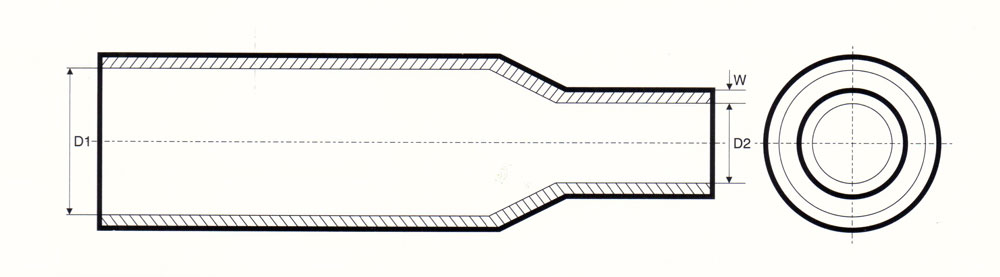

Specification

CYG-MT(2:1)

| Specification | Dimension before shrinkage(mm) | Dimension before shrinkage(mm) | Continuous packing (m/plate) | Quantity per reel cassette packaging | ||

|---|---|---|---|---|---|---|

| Diameter(D) | Thickness(T) | Diameter(d) | Thickness(t) | |||

| Ф2.4 |

≥2.4

|

0.27±0.05

|

≤1.2

|

0.51±0.08

|

30

|

2000

|

| Ф3.2 |

≥3.2

|

0.27±0.05

|

≤1.6

|

0.51±0.08

|

30

|

2000

|

| Ф4.8 |

≥4.8

|

0.27±0.05

|

≤2.4

|

0.51±0.08

|

30

|

2000

|

| Ф6.4 |

≥6.4

|

0.32±0.06

|

≤3.2

|

0.64±0.08

|

30

|

1500

|

| Ф9.5 |

≥9.5

|

0.32±0.06

|

≤4.8

|

0.64±0.08

|

30

|

1500

|

| Ф12.7 |

≥12.7

|

0.32±0.06

|

≤6.4

|

0.64±0.08

|

30

|

500

|

| Ф19.1 |

≥19.1

|

0.36±0.06

|

≤9.5

|

0.76±0.08

|

30

|

500

|

| Ф25.4 |

≥25.4

|

0.45±0.08

|

≤12.7

|

0.89±0.08

|

30

|

250

|

| Ф38.1 |

≥38.1

|

0.50±0.08

|

≤19.1

|

1.02±0.15

|

30

|

250

|

| Ф50.8 |

≥50.8

|

0.58±0.08

|

≤25.4

|

1.14±0.18

|

30

|

250

|

| Contraction ratio | Dimension before shrinkage(mm) | Dimension after full contraction(mm) | Continuous packing (m/plate) | Quantity per reel cassette packaging | ||

|---|---|---|---|---|---|---|

| Diameter(D) | Thickness(T) | Diameter(d) | Thickness(t) | |||

| Ф2.4 |

≥2.4

|

0.22±0.05

|

≤0.8

|

0.53±0.08

|

30

|

2000

|

| Ф3.2 |

≥3.2

|

0.22±0.05

|

≤1.1

|

0.58±0.08

|

30

|

2000

|

| Ф4.8 |

≥4.8

|

0.22±0.05

|

≤1.6

|

0.58±0.08

|

30

|

2000

|

| Ф6.4 |

≥6.4

|

0.22±0.05

|

≤2.1

|

0.58±0.08

|

30

|

1500

|

| Ф9.5 |

≥9.5

|

0.20±0.05

|

≤3.2

|

0.61±0.08

|

30

|

1500

|

| Ф12.7 |

≥12.7

|

0.20±0.05

|

≤4.2

|

0.61±0.08

|

30

|

500

|

| Ф19.1 |

≥19.1

|

0.20±0.05

|

≤6.4

|

0.61±0.08

|

30

|

500

|

| Ф25.4 |

≥25.4

|

0.20±0.05

|

≤8.5

|

0.64±0.08

|

30

|

250

|

| Ф38.1 |

≥38.1

|

0.30±0.06

|

≤12.7

|

1.00±0.15

|

30

|

250

|

| Ф50.8 |

≥50.8

|

0.30±0.06

|

≤17.0

|

1.00±0.18

|

30

|

250

|

Note: Other sizes and colors can be special order