Material:

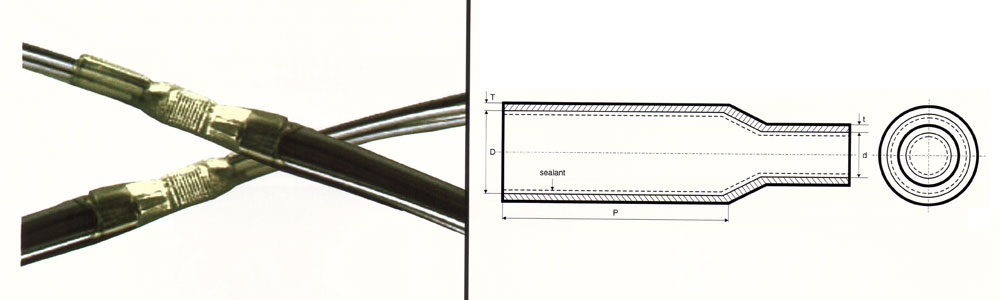

Outer: cross-linked modified semi-rigid polyolefin resin

Inner layer: hot melt adhesive

Shrink ratio: 4: 1

Features:

- Higher shrink ratio, for the quilt was larger diameter coverage;

- Transparent;

- Semi-rigid polyolefin material, higher mechanical properties and wear resistance,perform stress harness connector and terminal solutions at an excellent abrasion resistance and protection;

- Thicker layer of hot-melt adhesive, having excellent sealing performance,effectively resist fluid and moisture intrusion;

- Excellent oil resistance, particularly suitable for automotive interior environments;

- Operating temperature: -40 ℃ ~ + 130 ℃, applicable to a wider temperature range;

- Start shrink temperature: 110 ℃, full recovery temperature: 135 ℃.

Applications: This product is designed for automotive wire harness and piping requirements and specific design, it can be widely used with visual requirements of a variety of automotive wiring harness insulation seals, and other lines and terminals at the resumed indirect local stress relief and abrasion performance protection.

Introduction

|

Item

|

Test method

|

Indicator

|

Values

|

|

Longitudinal length change rate

|

ASTM D2671

|

0-10%

|

5%

|

|

Tensile strength

|

ASTM D2671

|

≥10.3MPa

|

18.87MPa

|

|

Elongation at break

|

ASTM D2671

|

≥250%

|

330%

|

|

Thermal aging

|

175℃±2℃,168h

|

Without dripping, flowing or crack

|

Qualified

|

|

Water absorption

|

ASTM D570

|

≤1.0%

|

0.5%

|

|

Volume resistivity

|

ASTM D2671

|

≥1×1012Ω•㎝

|

9.0×1014Ω•㎝

|

Specification

| Item | Test Method | Specifications | Test Value |

| Operation Temperature Range | ASTM D 2671 | 40ºC to 130ºC | |

| Shrink Temperature | Company standard | 110 ºC –135 ºC for jacket | |

| Tensile Strength | ASTM D 2671 | ≥10.3 MPa | 18.87 MPa |

| Longitudinal Change | ASTM D 2671 | 0 to -10 % | 5% |

| Elongation at Break | ASTM D 2671 | ≥250% | 330% |

| Aging at 168h,175℃±2℃ | ASTM D 3032 | No cracking | Pass |

| Water Absorption | ASTM D 570 | ≤1.0 % | 0.5% |

| Volume Resistance | ASTM D 2671 | ≥1.0 x 1012 (Ω.cm) | 9.0 x 1014 (Ω.cm) |

Size(mm)

| Type | As supplied | After recovery | ||

| Min ID(mm) | Max ID(mm) | Adhesive wall (mm) | Total wall(mm) | |

| CB- 4000-1 | 5.72 | 1.27 | 0.56 | 1.20 |

| CB- 4000-2 | 7.44 | 1.65 | 0.76 | 1.52 |

| CB- 4000-3 | 10.85 | 2.41 | 1.02 | 1.91 |

| CB- 4000 -4 | 17.78 | 4.45 | 1.37 | 2.41 |